Codename : Westfort Heart of Oak Alethorpe

While researching recipe ideas, I discovered the notion of adding oak chips to a beer after it has completed the first week of fermentation. The title is loosely inspired by the song Heart of Oak, an anthem used by many Commonwealth navies.

Ingredients

- 2 lbs 10 oz Maris Otter malt (3.8L)

- 1 oz Caramel malt (120L)

- 1 oz Rye malt (3.5L)

- 0.5 oz Black malt (450L)

- 0.20 oz Cascade hops at 60 minutes

- 0.20 oz Willemette hops at 15 minutes

- ¼ tsp Irish Moss (optional) at 15 minutes

- ¼ tsp yeast nutrient (optional) at 15 minutes

- 0.20 oz Willemette hops at 10 minutes

- 0.20 oz Willemette hops at 5 minutes

- 0.20 oz Fuggle hops at 0 minutes

- 6 ml Nottingham Ale yeast

- 1o grams toasted oak for secondary fermentation

Vital Stats

Anticipated ABV : 7.0%

Anticipated IBU : 45

Anticipated SRM : 15

Target OG : 1.070

Pre-boil SG : 1.046

Target FG : 1,017

Brewhouse (in)efficiency : 67%

Brew Day

- Prepare 7.8L strike water, 159F.

- Add the milled grains to the bag.

- Place the bag in the hot water, set the timer for 75 minutes, and maintain the temperature at 152 F.

- Calibrate the sonic screwdriver.

- Lift the bag out of the water, and allow it to drip into the pot. Every bit of sugar that can be extracted will benefit the end ABV.

- Bring up to a boil, 212F, set the timer for 60 minutes. Add hops, yeast nutrient and Irish Moss as prescribed above.

- Sanitise everything required for fermentation.

- Cool to room temp, an ice-bath or a snowbank work effectively.

- Prepare yeast mixture.

- Add wort to the jug. Pitch yeast.

- Store in a cool place for primary fermentation for 7-14 days.

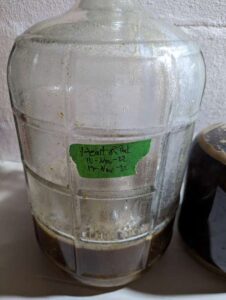

Secondary Fermentation

- If you have a second carboy, sanitise it, allow it to dry, and add the toasted oak.

- Siphon the contents from the primary carboy to the new carboy.

- Don’t have a second carboy? Just add it to the existing one..

- I am allowing the oak to infuse flavour for a week, feel free to extend the time for more oaky goodness.

Bottling Day

- Sanitise everything required for bottling.

- Transfer from carboy to bottling pot.

- Prepare 24g corn sugar with enough hot water to dissolve it. Add to pot.

- Bottle.

- Preferably conduct bottle conditioning for at least 6 weeks. You can crack one open early, but you might be disappointed. You have been warned.

Brew Notes

- Requisite gravity achieved, although I had to steep the grain for 90 minutes instead of the planned 75 minutes. Really not sure why.

- I use cloth tea bags to contain the mess of the dry hops, two of them opened during boil and gooed up the wort, hopefully it will settle out.

Brew day : 10-Nov-2022

Bottling day :

To provide the best experiences, we use technologies like cookies to store and/or access device information. Consenting to these technologies will allow us to process data such as browsing behaviour or unique IDs on this site. Not consenting or withdrawing consent, may adversely affect certain features and functions.

To provide the best experiences, we use technologies like cookies to store and/or access device information. Consenting to these technologies will allow us to process data such as browsing behaviour or unique IDs on this site. Not consenting or withdrawing consent, may adversely affect certain features and functions.